Printed Circuit Boards (PCBs) stand as the cornerstone of modern electronics, orchestrating electrical connections and components. Delving into the materials and structure of PCBs illuminates their critical role and diverse applications.

Core Materials in PCBs

-

Substrate:

- Serving as the PCB foundation, the substrate ensures structural stability. FR4, a glass-reinforced epoxy laminate, is preferred for its strength, affordability, and insulating qualities. For versatility, materials like polyimide or PEEK cater to flexible PCB needs.

-

Copper:

- Copper layers, laminated onto the substrate and then etched into traces and pads, facilitate conductivity. Its selection is due to superb electrical conductivity and the precision with which it can be worked.

-

Solder Mask:

- This protective layer over the copper wards off oxidation and prevents solder bridge formation. While traditionally green, other hues are also available.

-

Silkscreen:

- Atop the solder mask, the silkscreen layer adds essential labels and symbols for assembly guidance, typically rendered in white but available in other colors.

Additional Elements and Coatings

-

Surface Finish:

- Surface finishes like HASL, ENIG, and OSP safeguard exposed copper circuits and bolster solderability.

-

Through-Hole Plating:

- Copper plating in through-holes establishes conductive vias, linking the PCB’s various layers.

-

Other Materials:

- Gold for contact fingers and specific adhesives for multi-layer board lamination are also integral.

Considerations in PCB Material Choice

-

Electrical Properties:

- Selection hinges on achieving desired conductivity, insulation, and resistance levels.

-

Thermal Properties:

- Materials must withstand component-generated heat and soldering temperatures without degrading.

-

Mechanical Durability:

- PCBs require resilience to endure handling, mounting, and environmental challenges.

-

Cost and Manufacturability:

- The balance between affordability and ease of fabrication guides material choices.

PCBs are intricate entities, composed of materials meticulously chosen for their electrical, mechanical, and thermal properties. The synergy of substrates, copper, solder masks, and additional elements renders PCBs indispensable in electronics. As material science and manufacturing techniques evolve, PCBs’ roles and capabilities continue to expand, reflecting the dynamic nature of the electronics industry.

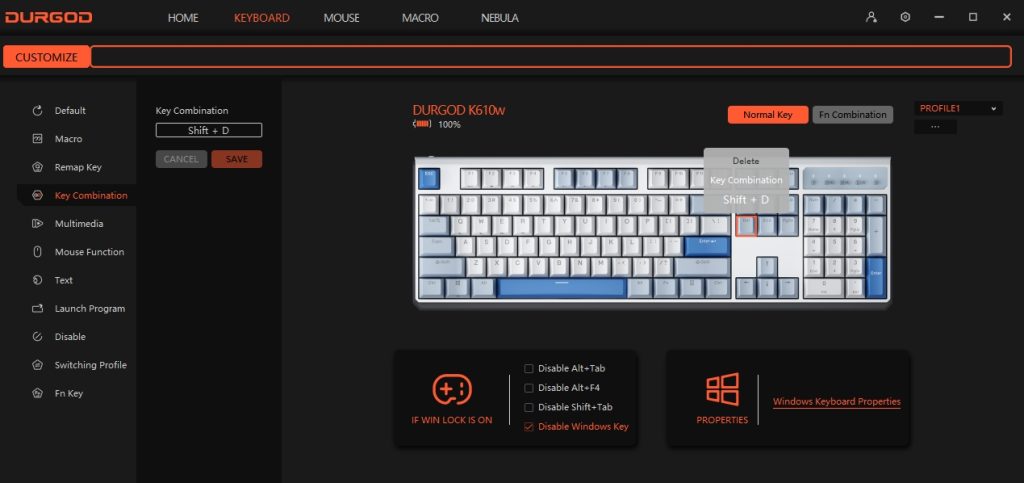

For more knowledge of mechanical keyboards, visit DURGOD.